25th May 2017

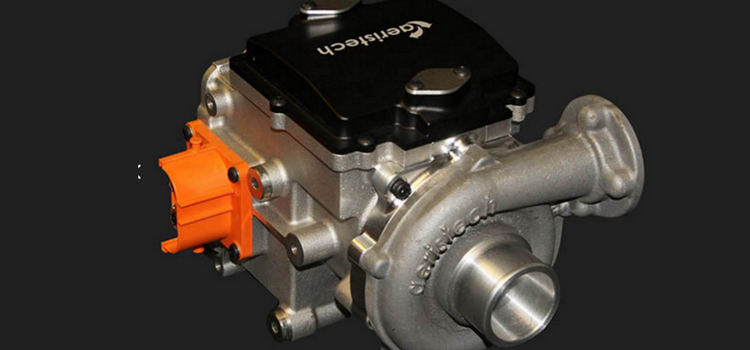

The new Aeristech 48V eSupercharger suitable for downsized engines of less than about 1.2-L.

Richard Wall believes an e-supercharger could be the only boost technology required for small, downsized city car engines in traffic dense urban environments, particularly those in China. As the CEO of Aeristech, a U.K.-based boosting-technology specialist, Wall sees advances in e-supercharger capability and 48V systems providing a viable opportunity to “leapfrog” what has become common use of small turbocharger, or turbo-plus-e-supercharger configurations.

To that target, the company is developing its 48V eSupercharger suitable for downsized engines of less than about 1.2-L. The jump to sole e-boost and use of 48V (regarded as necessary to provide required boost levels) raises questions of cost, always significant in small car production. Wall told Automotive Engineering that he hears “wildly different” estimates of the cost of transitioning from 12V to 48V.

“Certainly the vehicle’s BoM [bill of materials] cost is impacted very little if at all, with 48V even saving copper compared to 12V,” he said. If an OEM has decided to add 48V to a small vehicle in order to support other electrified subsystems, it makes the Aeristech machine “commercially viable” compared to a conventional turbocharger, Wall claimed.

Incumbent turbocharger technology does not provide efficient boosting at low engine speeds, Wall argues, adding that the rate of engine downsizing is being restricted. This is one of the main reasons that real-world emissions “are so far detached [in terms of error] from published test figures,” he noted.

Centrifugal compressor

The Aeristech eSupercharger used on its own would meet city car performance and emissions requirements because its higher shaft speeds (up to 120,000 rpm), capacity for continuous operation and enhanced compressor efficiency are enabled by patented motor technology, he explained. The prototype eSupercharger recently completed “without issue” more than two million boosting events, to meet or exceed a stringent OEM durability cycle, the company reports.

Strong interest in the company’s technology from developing markets led Aeristech to successfully demonstrate downsizing possibilities in a recent collaboration with Mahle Powertrain Ltd. The project, which used a 161-kW/L, C-segment demonstrator vehicle, has expanded to various pre-development and demonstrator programs for specific vehicles in the region, Wall reported.

Urban duty cycles in Asia dictate a requirement for low-rpm torque, rather than outright power: Such drive cycles are “ideally suited to the use of electric air charging, which offers immediate response and torque from idle,” Wall said.

He regards the main differentiator between his company’s eSupercharger and competitors’ solutions as being the ability to deliver high pressures and volume continuously. Typical boost applications require 1.5-2.0 bar and mass-flow rates in excess of 100 g/s, figures that Aeristech has demonstrated it can provide with more if needed. This characteristic, in addition to being electrically driven and controlled by the engine ECU, provides almost instant matching of inlet airflow to engine demand.

The result is technology that Wall claims is “an ideal sole source of boost” for small- displacement engines.

Most electric motors are restricted by thermal constraints that prevent continuous full-power operation. Aeristech’s patented control architecture “leads to a well optimized control and motor design; this helps with the thermal management challenge that has traditionally limited the continuous performance of electric charging technologies,” Wall said. He claims the eSupercharger’s 120,000-rpm shaft speeds enable the use of a centrifugal compressor, which is claimed to be lower cost and more efficient than Roots or screw-type units.

A ped-pro enabler

A big plus is that the design of a stand-alone electric supercharger exempts it from crankshaft power limitations. Available power need not limit performance, nor should it be diminished to satisfy instantaneous demand at the supercharger. And the vehicle’s complete electrical system can be used as a reservoir at times of high power demand. This enables alternator regeneration of charge over time, which can be used to sustain optimal operating conditions for improved fuel efficiency.

“Flexibility is a crucial benefit of the eSupercharger,” Wall added. Reduced inertia promotes fast speed adjustment and the lack of mechanical drive provides near-modular capability for optimum engine compartment packaging. This helps enable engine configuration needed to meet other factors such as improved “ped-pro” (pedestrian impact performance).